BarhaleEnpure JV were engaged by Yorkshire Water to deliver the construction elements of a new Integrated Wetlands treatment works in Clifton. This nature-based solution has been a first for Yorkshire Water and provides a blueprint for sustainable wastewater treatment across the industry.

The team worked closely with the design and delivery partners to develop the wetlands solution into a workable outcome.

The final constructed solution comprised:

• 5 no treatment cells (settlement ponds and shallow marshes)

• New scum board in the existing primary tank

• Inlet and outlet flow metre chambers to enable

analysis of the flow for the Environment Agency

• Outfall point, a precast concrete unit to take flows into Kearsley Beck

• 430m of post and rail fencing, to be in keeping with the area

• Additionally, the team undertook a 12 week sampling

programme which was extended by 40 weeks to analyse

the performance of the wetlands over a longer period

Birmingham is served by a single source of potable water; from Wales, via the 110 year old Elan Valley Aqueduct (EVA) and Frankley Water Treatment Works (WTW). The aim of this collaborative project was to work with Severn Trent Water to provide resilience for this primary clean water supply. The Birmingham Resilience Project (BRP) will provide an alternative water supply for periods of up to 50 days every two years. This will enable a full shut down of the EVA allowing STW to carry out essential maintenance on the Aqueduct.

Barhale were engaged by STW to deliver a new 26km, cross country steel pipeline, as well as all associated pump stations and implementations for ‘Operational Readiness’. Overall, the project spanned 20 individual sites and employed 220 personnel at its peak.

The Queen Elizabeth II (QEII) Reservoir is a raw water reservoir in

South West London that is owned and operated by Thames Water.

The reservoir holds over 19 million litres of water, equating to 10% of

the raw water storage for London. Once treated, this provides clean

drinking water for millions of people across Surrey and London.

Barhale were engaged by Thames Water to complete this £11m tunnel

relining project to guarantee the integrity of the aged inlet and outlet

tunnels. The goal of the project was to strengthen the tunnels and

prevent any leakage at this crucial clean water asset.

As part of the enabling works for the construction of an Energy Recovery Facility (ERF) at the EcoPark in North London by the North London Heath and Power Project (NLHPP), Barhale were contracted to divert the Thames Water-owned Chingford and Angel public sewers.

The new energy recovery facility at the Edmonton EcoPark will deal with up to 700,000 tonnes of waste from the seven north London boroughs per year. It will generate efficient, low carbon heat and power to serve the needs of 127,000 homes.

Drawing on decades of experience delivering similarly complex schemes, Barhale developed an innovative design and construction method for the sewer diversions. This not only accelerated the programme and reduced the cost, but it also minimised the potential disruption to the community and it significantly reduced the environmental impact. Tailored social value initiatives also ensured that the team contributed to the creation of a lasting legacy, as part of the wider project.

As part of the works on the Tideway project, Barhale was awarded

a contract bythe Ferrovial Construction Laing O’Rourke JV (FLO) on

the central section to construct the tunnelling and civils elements

between the existing Combined Sewer Outlet (CSO), located under

the Victoria Embankment river wall and the new main tunnel being

constructed under the River Thames. Barhale successfully undertook

the pilling, dewatering, shaft sinking (by using three methods), tunnel

construction, earthworks and RC structures.

Barhale constructed a secant pile wall behind the Victoria

Embankment river wall with the support of Expanded, one of our

specialist supply chain partners. The logistics involved working in

a narrow footprint access road, leaving a gap of 300mm between

the piling rig and the site hoarding. After completion of the secant

pile wall, 2 gas mains (30” and 36” medium and low pressure) were

diverted behind the wall. Inside the cofferdam, Barhale lifted a 50T

pilling rig to construct 70no 1200mm contiguous piles for the new

river wall, and 42 600mm piles for the new CSO foundation.

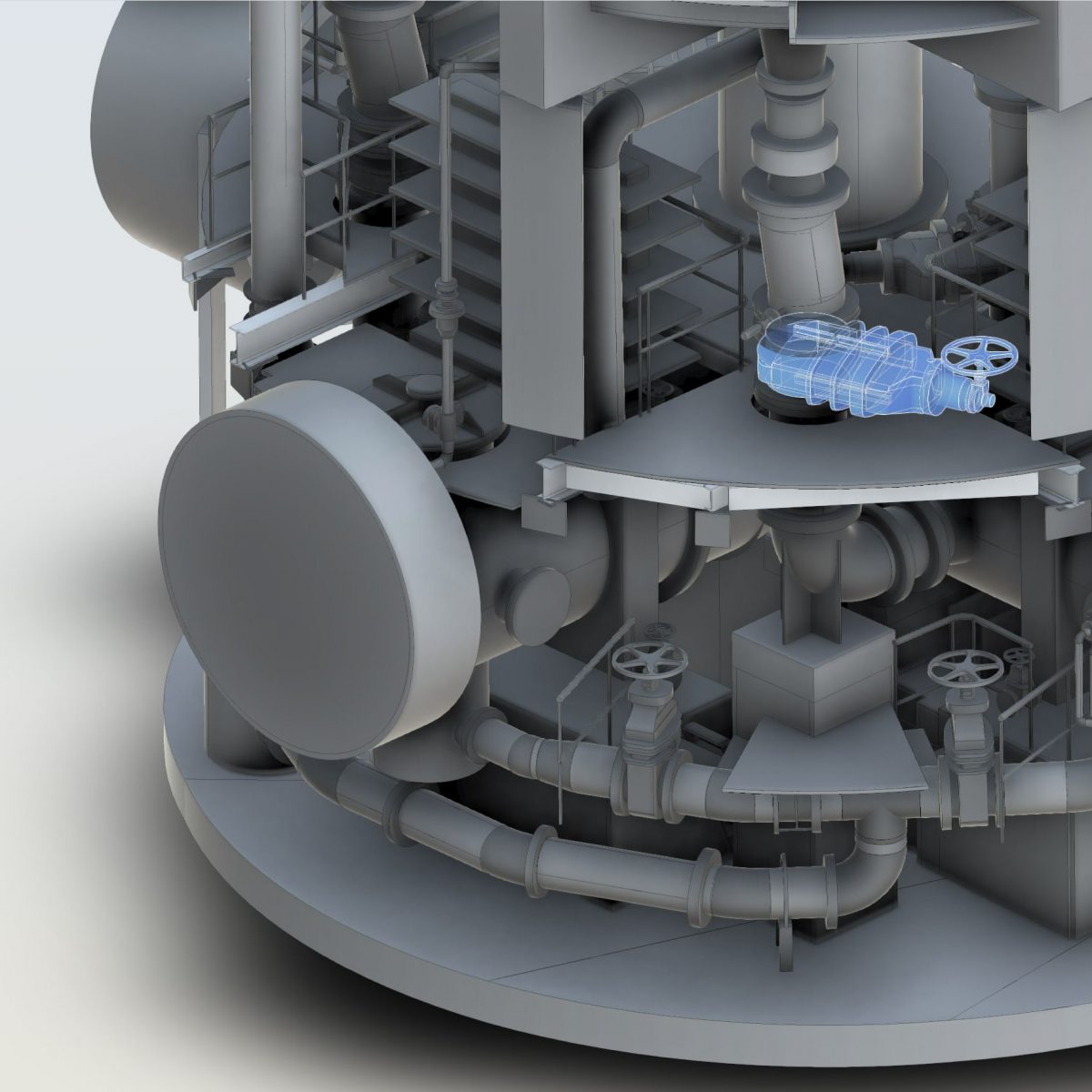

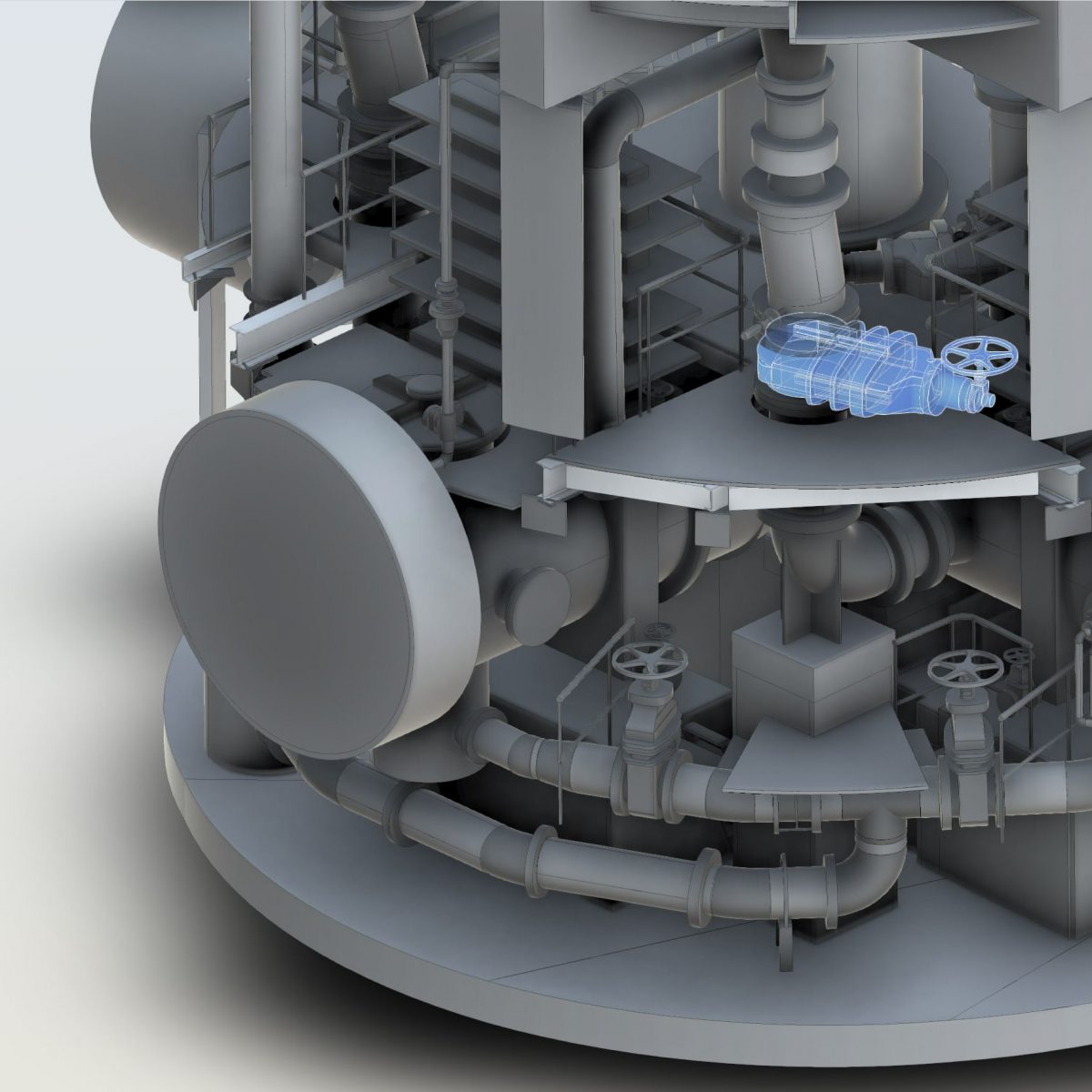

The Thames Water Ring Main (TWRM) in London is an 80km long, 2.5m diameter tunnel built between 1988 and 1994 to take water from five treatment works and transfer flows via pumping stations housed in shafts along the route. It is a major part of London’s water supply infrastructure and carries an average daily flow of 0.3 x109 gigalitres – a little under one-sixth of the capital’s daily demand.

Barhale was appointed by Thames Water to carry out refurbishment works at Barrow Hill Shaft, one of a total of 22 on the ring main.

Located at St. Edmunds Terrace on the edge of Primrose Hill in North London, Barrow Hill is the deepest of the shafts at 80m deep and also the biggest with a four way tunnel connection at its base.

As part of Southern Water’s AMP6 Capital Works, Barhale were

contracted to build a first time Waste Water Treatment Works (WWTW)

for the Village of Mountfield, Sussex. Despite challenging conditions

due to the site location, this being in close proximity to residential

properties and within a flood plain, Barhale completed the works on

time, to the satisfaction of the local community. Close collaboration

with Southern Water and the latter’s expert input throughout both

the design and construction stages played a key role in achieving this

outcome. Barhale’s established expertise in waste water treatment

works, combined with a proactive, innovative, and flexible approach,

further facilitated successful delivery.

As part of the wider Thames Tideway scheme, Barhale were engaged

to design and build a new 60m long, 2.8m diameter, steel pipeline

within the Beckton Waste Water Treatment Works (WWTW). The new

pipeline will connect the existing Lee Tunnel to a new Storm Tunnel,

and substantially increase storage capacity during flooding, thus

reducing the amount of sewage being released into the Thames River

yearly. Barhale designed, fabricated and installed most of the elements,

including all the steel work. We provided technical and engineering

support to integrate our works into the client BIM system. We also

delivered several specialist design, fabrication and lifting solutions to

overcome numerous restrictions. Now complete, the works are part of

the permanent Thames Tideway solution.

As part of works on the west section of the Thames Tideway Tunnel scheme, Barhale were contracted by the BAM Nuttall Morgan Sindall Balfour Beatty (BMB) joint venture to construct a series of complex underground structures that would intercept the sewage overflows from the West Putney Storm Relief Sewer for transfer to the main Tideway tunnel beneath the River Thames.

The scope of works included the construction of a 35m deep x 6m internal diameter drop shaft and a 210m long x 3m outside diameter connection tunnel.

Surface level works include 6m deep reinforced concrete (RC) interception chambers, a RC culvert and a RC MEICA building, comprising of electrical intake room, telemetry room and control room for system alarms and automated actuated valves (installed by others).

Barhale also built an 800m long, 4m wide access road, and installed additional sections to address Environment Agency and Local Authority requirements related to existing flood defences and protected trees in the proximity of the works.